Side Stream Filtration System

The non-chemical way of water treatment

The Problem

The suspended solid in condenser loop

Increases viscosity of the water and increase energy consumption of water being pumped.

Deposit in the bottom provides hiding places for bacteria Legionellosis

Settles down in the lowest point usually in chiller affects heat transfer

most chiller are groove and most chiller are grooved so this affects heat transfer

At the same time when the water goes the copper, it grinds the copper down because it begans acting like sandblast due to residue

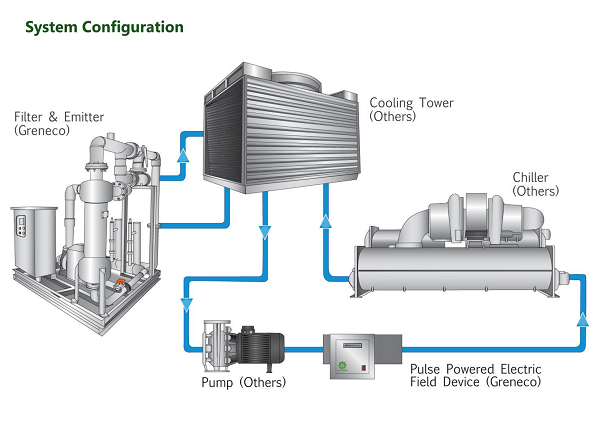

Fully Automated Side Stream Filtration System

Sidestream filtration filters a portion of the flow (much like a swimming pool filter) to remove sediment and other impurities. A sidestream filtration is composed of a rapid sand filter or high-efficiency cartridge filter to cleanse the water. These systems draw water from the sump, filter out sediment and return the filtered water to the tower, enabling the system to operate more efficiently with less water and chemicals. Sidestream filtration is particularly helpful if your system is subject to dusty atmospheric conditions, and can turn a trouble system into a more trouble-free system.

Filtration system with Sweeping Nozzles

- Assist to reduce suspended solid accumulation in the cooled basin.

- Avoid abrasive wear of the condenser enhance tube surface.

- Minimized bacteria growth brought by suspended solid accumulation.

- Reduce the chemical dosing or improved the water treatment effectiveness on bacteria

and algae control.

Pre-Process: The Before

A Quick Snapshot and Overview

Reliable Motorized Valve

Omron PLC

Danfoss Soft Starter

Stainless Steel Filter (<30 micron)

Before Filtration System On, Water is Cloudy

Sludge and Debris Deposited on the Cool Basin

Post Process – AFTER

After Filtration is On

Sweeping Nozzle Effect (view 1)