The Great Little Water Company has developed a special design to turn rainwater into perfect cooling tower water. The Clean CT-01™ Intelligent System for condenser water treatment is ideal for use with rainwater harvesting. Such a system has been installed for example at a hypermarket near Kuching with two times 500 ton chillers and two times 700 ton cooling towers. The project was a huge success mainly for the following reasons:

- Heat transfer efficiency of the chillers is maintained at unusually high levels. This means the system runs at the best energy efficiency levels just like a perfectly new system. The way to track this efficiency is to monitor STD = Small Temperature Difference (also called “approach temperature”) which measures the difference between cooling water and refrigerant. The smaller this difference is, the better the heat is transferred from one medium to the other. Once dirt or scale or biofilm cover the inside of the heat exchanger tubes, the values for STD go up. Please refer to the Graph 1 below to see the trend.

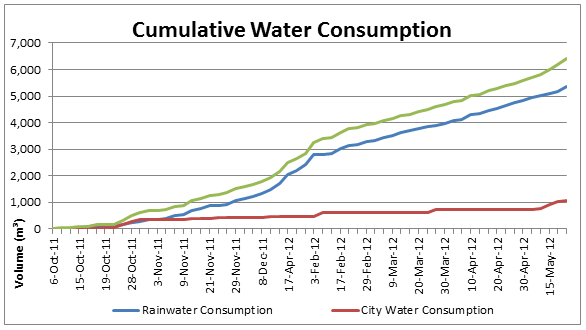

- Great water savings of over 5,000,000 Litres were achieved in only 7 months. And these savings continue day to day as the tropical rain fills up the site’s rainwater storage tanks. A good 80% of the site’s water consumption is covered by rainwater. Cooling systems using cooling towers typically require tens or even hundreds of cubic meters of water every day only to make up for the evaporation, and in this context harvested rainwater is perfect for use in cooling towers.

Graph: Small Temperature Differences for condenser and evaporator water, tracked over a 7 months period. Almost all condenser STD readings are below 1.0ºF which is rarely seen at other comparable sites. This is a sign of an exceptionally clean system with no impurities getting in the way of good thermal heat transfer.

Graph: Over 5,000,000 Litres of water have been saved in this 7 months period. Rainwater has provided a good 80% of the cooling system’s water demand.

Please contact us for quotes, discussions or further questions.

Please click here for more numbers and further details on this case study.